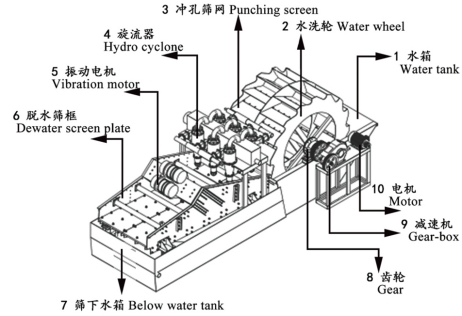

Combined Wheel Fine Sand Washing Recycling Machine

We manufacture Combined Wheel Fine Sand Washing Recycling Machine. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Description

The sand washing recycling machine integrates sand washing and dewatering and recycling of fine sands. The machine connects the fine sand recycling machine with the sand washing machine. The structure is reasonable, the floor space is small, and the investment cost is lower than the price of the two equipments. It completely solves the problem that theloss of the fine sandis difficult to control with traditionalsand washing machine. The sand washing part has the same function as the general wheel type sand washer, and is used for washing sand; and the recycling machine part can be combined according to the customer's demand for fine sand recovery and dehydration.

2. Features

1. The sand washing recycling machinecombines the advantages of sand washing machine and fine sand recycling machine, which has the functions of sand washing and fine sand dewatering and recycling. The products are cleaner than traditional machine and the grade is better.

2. Higher work efficiency, low energy consumption, environmental friendly, reducing the dredging pressure of the settling pond.

3. Reasonable structure, small floor space, simple installation and low investment cost.

4. Long service life, low maintenance cost and convenient replacement of spare parts.

5. Different models and configurations can be customized according to customers’ needs.

3. Structure and Working Principle

The mixtureof sands and water enters the water tank of sand washing recycling machine, and is rotated by the impeller to screenand cleanthe sands uniformly to remove impurities covering the surface of the sand. The sands picked up by the wheel bucket are dehydrated by the dewatering screen at the front end of the sand washing. At the same time, the waste water overflowing from the water tank (including a large amount of fine sand, mud, dust and other impurities)is transported to the centrifugal separator through the slurry pumpto carry out high-efficiency centrifugal grading and concentration. The fine sands are discharged into the dewateringscreen through the grit nozzleto achieve fine sand recovery and dehydration of all sands.

4. Technical Data

Model | Power (kw) | Hydrocyclones (mm) | Feeding Size (mm) | Capacity (t/h) | Dimension (mm) |

SK22-25 | 16 | 250 | <10mm | 30-60 | 5500*1500*2200 |

SK26-35 | 29 | 350 | <10mm | 40-70 | 6500*2950*2700 |

SK28-70 | 47 | 2*350 | <10mm | 60-100 | 7500*4500*2800 |

SK30-70 | 51 | 2*350 | <10mm | 60-150 | 7500*4836*3080 |

5. Pictures

6. Working Site

7. Latest News

8. Recommendation

1. Spiral Washer

2. Sand Making Machine

3. Vibrating Screen