Mineral Separation Plant

Plant Small Scale Alluvial with Crushing Processing Washing

We manufacture Gold Mining Plant Small Scale Alluvial with Crushing Processing Washing. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

Gold mines have high mining value, so gold mininghas the most mining methods and is the most complicated. As the grade of ore is reduced, the requirements for gold mining technology are increasing. In recent years, new processes, new technologies and new equipment have been developed and put into the gold ore beneficiation production. As the varietyof gold ores including gravel mine, vein gold deposits, rock gold, gold oxides, gold sulfides, etc., there are many gold mining methods, such as flotation technology, CIP process, CIL process, cyanide processand amalgamation. Gravity separationand flotation process are the most common used.

2. Methods

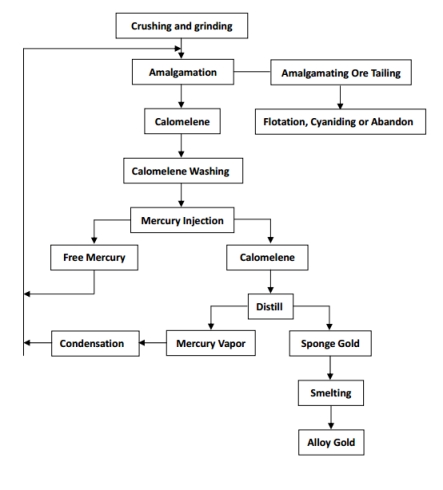

Amalgamation

The production line of amalgamation gold mining equipment is divided into two types: internal mixed mercury and external mixed mercury. The equipment adopted includes amalgamating table, amalgamated chute, ore mill, amalgamation barrel and small ball mill or rod mill. In the treatment of gulch-gold, amalgamation is usually adopted to separatethe gold ore and heavy sand mineral. In vein gold mines, heavy sand mineral is usually used as part of a combined process with flotation, gravity concentration, cyanidation, etcto collect coarsefree gold.

The amalgamation gold mining equipment has a simple process, easy operation and low cost. However, mercury is a toxic substance and is very harmful to the human body. Therefore, the concentrator that uses the amalgamation gold mining equipment should strictly abide by the safety technical operating procedures to minimize the harm of mercury vapor and metallic mercury to the human body.

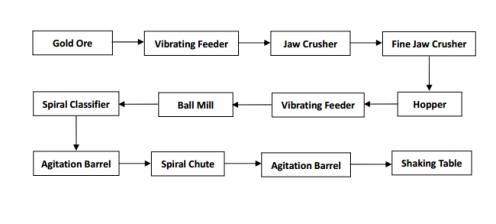

Gravity Concentration

Gravity concentrationis one of the oldest and most popular methods of gold mining. Gravity concentrationis suitable for processing ore or other materials with a large density difference between useful minerals and gangue. It is an effective method for treating coarse, medium and fine (substantially bound to be larger than 25 mm, 25-2 mm, 2 to 0.1 mm) ore. According to different equipment used, gravity concentration can be divided into jigging beneficiation, shaker beneficiation, chute beneficiation, centrifugal beneficiation, pneumatic separation, etc. The most common gravity concentration equipment is jiggers, shaking tables and chutes.

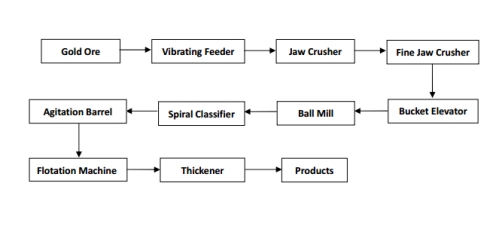

Flotation

Flotation is one of the most widely used methods for processing gold ore in goldmining. In most cases, the flotation is used to treat sulfide minerals containing gold ore with high floatability. Flotation cannot only maximize the gold into the sulfide mineral concentrate, but also waste tailingsand reduce the costs. Since the flotation method can only concentrate gold in various sulfide mineral concentrates and cannot finally obtain the finished gold, sonot many factories use a single flotation process. Generally the flotation is used as apart of associated process.

The gold mine is subjected to coarse crushing by a jaw crusher for primary crushing. The crushing process can adopt two-stage closed circuit or three-stage open circuit according to the beneficiation process. The crushed oresare sent to the ball mill by the feeding device, and then the grinded ores are sent to a spiral classifier for washing and grading. Then the material is sent to the flotation machine through the mixing drum.The water in the mineral is removed by a high-efficiency concentrator, and then smelted by drying in a rotary dryer.

4. Working Site

5. Latest News

6. Recommendation

1. Flotation Machine

2. Ball Mill

3. Sand Dryer

Submit your inquiry and we will make prompt response with professional printing solutions.