Circular Vibrating Screen Sand Aggregate Custom-made with Large Capacity High Efficiency

We manufacture Circular Vibrating Screen Sand Aggregate Custom-made with Large Capacity High Efficiency. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

Circular vibrating screen is a kind of high-efficiency screening equipment widely used in mining, building materials, transportation, energy, chemical industry and other industries. It has the characteristics of strong excitation force, multi screening specifications, high efficiency, low noise, strong and durable. The advanced modular frame structure improves the service life of the equipment. Spring damping device reduces the impact on the foundation. The handling capacity and energy consumption of our company'svibrating screen have reached international advanced standards and are highly praised by customers in the industry.

2. Specification

Model | Layer | Screen Mesh (mm) | Capacity(m³/h) | Frequency(r/min) | Power (kw) | Angle (°) | Weight (kg) |

2YK1230 | 2 | 4-50 | 12-78 | 800-970 | 7.5 | 20 | 4200 |

3YK1230 | 3 | 4-50 | 13-80 | 800-970 | 7.5 | 20 | 4600 |

2YK1237 | 2 | 4-50 | 15-86 | 800-970 | 7.5 | 20 | 4600 |

3YK1237 | 3 | 4-50 | 16-90 | 800-970 | 7.5 | 20 | 5200 |

2YK1535 | 2 | 5-50 | 20-125 | 800-970 | 11 | 20 | 5890 |

3YK1535 | 3 | 5-50 | 21-125 | 800-970 | 11 | 20 | 6700 |

2YK1545 | 2 | 5-50 | 22-150 | 800-970 | 15 | 20 | 6330 |

3YK1545 | 3 | 5-50 | 22-150 | 800-970 | 15 | 20 | 6800 |

4YK1545 | 4 | 5-50 | 22-155 | 800-970 | 18.5 | 20 | 7800 |

2YK1548 | 2 | 5-50 | 23-162 | 800-970 | 15 | 20 | 6980 |

3YK1548 | 3 | 5-50 | 23-162 | 800-970 | 15 | 20 | 7700 |

4YK1548 | 4 | 5-50 | 23-162 | 800-970 | 18.5 | 20 | 8700 |

2YK1848 | 2 | 5-80 | 25-206 | 750 | 15 | 20 | 9080 |

3YK1848 | 3 | 5-80 | 32-276 | 750 | 18.5 | 20 | 9600 |

4YK1848 | 4 | 5-80 | 32-285 | 750 | 22 | 20 | 11100 |

2YK1854 | 2 | 5-80 | 32-312 | 800-970 | 18.5 | 20 | 10150 |

3YK1854 | 3 | 5-80 | 32-312 | 800-970 | 22 | 20 | 10840 |

4YK1854 | 4 | 5-80 | 32-336 | 800-970 | 30 | 20 | 12840 |

2YK2160 | 2 | 5-100 | 50-175 | 970 | 30 | 20 | 11780 |

3YK2160 | 3 | 5-100 | 50-475 | 970 | 30 | 20 | 12800 |

4YK2160 | 4 | 5-100 | 50-497 | 970 | 37 | 20 | 14800 |

2YK2460 | 2 | 5-100 | 65-550 | 970 | 37 | 20 | 15600 |

3YK2460 | 3 | 5-100 | 70-620 | 970 | 37 | 20 | 17600 |

4YK2460 | 4 | 5-100 | 80-680 | 970 | 45 | 20 | 19600 |

3. Features

1. Strong excitation, high screening efficiency, large capacity

2. The structuretends to be simplified, which helps to improve the manufacturing process and assembly accuracy of the equipment.

3.Various materials of screenmeshes are available to meet the requirements of different industries

4. The maintenance is simple and convenient, and the overall operation efficiency is improved significantly

5. Long lifespan, low noise, and steady resonance area.

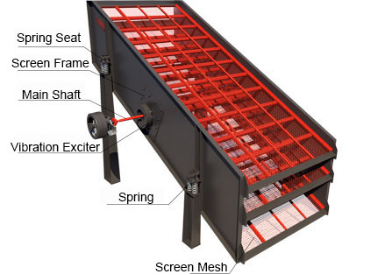

4. Structure and Working Principle

The circular vibrating screen is mainly composed of screen body, screen mesh, vibrator, spring damping device, and underbed and so on. The eccentricity block of exciterrotates with high speed under the drive of motor via the V-belt. The running eccentric block generates a large centrifugal force, stimulating the screen body to produce a circular movement of certain amplitude. The material is subjected to a continuous throwing motion caused by the impulse transmitted from the screen body on the inclined screen mesh. Materials smaller than the meshsize are sieved out by the circular vibrating screen.

设备

5. Pictures

6. Working Site

7. Latest News

8. Recommendation

1. Liner Screen

2. Jaw Crusher

3. Belt Conveyor