Screen & Feeder

Rotary Screen Drum Vibrating Sand Coal with Large Capacity High Efficiency

We manufacture Rotary ScreenDrum Vibrating Sand Coal with Large Capacity High Efficiency. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

The rotary screenis mainly used for the grading and screening of medium and fine materials. It is the special screening equipment widely used in power plants, coking plants, building materials, metallurgy, chemical industry, mining and other industries. It overcomes the problem of screen clogging that occurs when the circular vibrating screen and the linear screen screening high humidity materials, which improves the efficiency and reliability of screening. During operation the screen runs slowly and uniformly, impacts slightly, works stably and install easily. In addition, we can customize differentmodelsaccording to different material requirements and working environment to meet different production needs.

2. Specification

Model | Drum Size (m) | Angle | Rotate Speed (r/min) | Screen Mesh (mm) | Max. feeding Size (mm) | Capacity (m³/h) | Power (kw) | |

Mesh Size (2mm) | Mesh Size (30mm) | |||||||

YTS1030 | Φ1*3 | 5-7° | 22.5 | 2-30 | 60 | 10 | 60 | 4 |

YTS1040 | Φ1×4 | 5-7° | 25 | 2-30 | 60 | 11 | 80 | 4 |

YTS1230 | Φ1.2×3 | 5-7° | 20 | 2-30 | 70 | 12 | 100 | 5.5 |

YTS1240 | Φ1.2×4 | 5-7° | 20 | 2-30 | 70 | 14 | 120 | 5.5 |

YTS1250 | Φ1.2×5 | 5-7° | 20 | 2-30 | 70 | 15 | 140 | 5.5 |

YTS1530 | Φ1.5×3 | 5-7° | 17 | 2-30 | 80 | 18 | 150 | 5.5 |

YTS1540 | Φ1.5×4 | 5-7° | 17 | 2-30 | 80 | 18 | 150 | 7.5 |

YTS1550 | Φ1.5×5 | 5-7° | 17 | 2-30 | 80 | 20 | 180 | 11 |

YTS1560 | Φ1.5×6 | 5-7° | 17 | 2-30 | 80 | 22 | 200 | 11 |

YTS2040 | Φ2×4 | 5-7° | 12 | 5-60 | 90 | 25 | 250 | 15 |

YTS2050 | Φ2×5 | 5-7° | 12 | 5-60 | 90 | 30 | 300 | 15 |

YTS2060 | Φ2×6 | 5-7° | 12 | 5-60 | 90 | 35 | 350 | 18.5 |

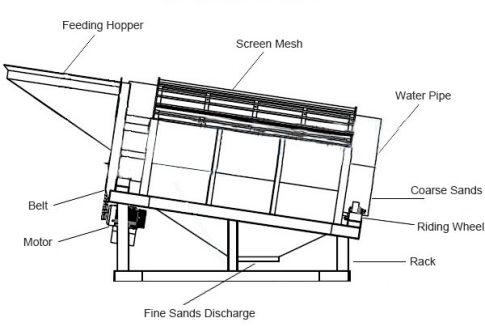

3. Structure and Working Principle

Rotary screen structure is simple, mainly consists of motor, reducer, roller device, rack and other parts.

The circular roller device is aslantmounted on therack, and the motor is connected with the roller device through the coupling through the reducer. When the material enters the drum, the drum rotates under the action of the motor, and the material moves in the drum in the direction of rotation of the drum. The screen meshes installed in the drum have different mesh sizes, and the qualified materials (under the screen) are discharged through the screen mesh. Unqualified materials (on the screen) are discharged through the end of the drum to complete the screening work. As the material is turned and rolled inside the drum, the stuck material can be ejected to prevent the screen mesh from being blocked.

4. Features

1. Widely use, high screening efficiency.

Rotary screenis widely used for screening various types of materials. No matter poor quality coal, slimeor bituminous coal and other materials, it can processsmoothly. The machine can be equipped with a cleaning device. No matter how dirty or miscellaneous materials enter the screening cylinder,the screen can handle them efficiently.

2. Large handling capacity, low energy consumption.

At the same size, the effective screen area of the rotary screen is large, so that the material can fully contact the screen, so the handling capacity per unit time is large. It fully utilizes the gravity effect of the material in the operation, so the motor power is small and the energy consumption is only half that of other screens.

3. Environmentalfriendly, low noise.

The entire screen body can be sealed to avoid dust and block splash during screening. The screen rotates at a low speed and has a sealed cover so that noise cannot be transmitted to the outside.

4. Easy maintenance.

The upper coverof rotary screen can be disassembled. It does not affect the normal operation of the machine after unpacking, and the maintenance is very convenient.

5. Pictures

6. Working Site

7. Latest News

8. Recommendation

1. Circular Vibrating Screen

2. Sand Making Machine

3. Belt Conveyor

Submit your inquiry and we will make prompt response with professional printing solutions.