PEX Industrial Mini Rock Fine Jaw Crusherfor Secondary Crushing

We manufacture PEX Industrial Mini Rock Fine Jaw Crusherfor Secondary Crushing. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Brief Introduction

The fine jaw crusher is a kind of crusher with smaller crushing chamber. Unlike primary jaw crusher, it is mainly used for medium or fine crushing operations. The fine crusher is mainly suitable for small and medium-sized mines, building materials, road construction, silicate and chemical industries. The feeding sizeof the crusher should be no more than 120mm. Compared to similar products,the crusher made by SANKAY has the characteristics of stable operation, large crushing ratio, high output, low energy consumption, low noise and low operating cost.

2. Technical Parameter

Model | OpeningSize (mm) | Max Feeding Size (mm) | Discharge Opening (mm) | Capacity (t/h) | Power (kw) | Dimension (mm) | Weight (t) |

PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 670×820×760 | 0.81 |

PE-150×750 | 150×750 | 125 | 10-40 | 5-16 | 15 | 1050×1490×1055 | 3.8 |

PEX-250×750 | 250×750 | 210 | 25-60 | 15-30 | 22 | 1750×1500×1420 | 5 |

PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 30 | 1940×1650×1450 | 7 |

PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-65 | 37 | 1940×1850×1450 | 7.7 |

PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 55 | 2720x1950x1600 | 15.6 |

3. Features

1. Simple structure, convenient to use and maintain;

2. Energy saving and environmental protection, reducing energy consumption.

3. Large crushing ratio and uniform product size;

4. Stable performance, small particle size, high quality of products;

5. Low noise, less dust.

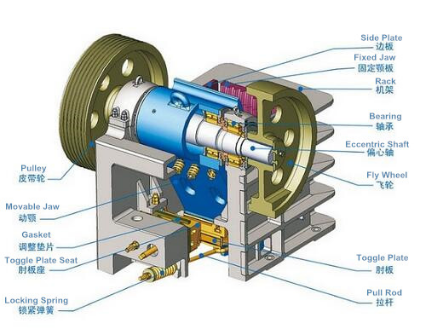

4. Working Principle

In the working process, thefine jaw crusher drives the belt and the pulley by the electric motor, and moves the moving jaw up and down through the eccentric shaft. When the moving jaw descends, the angle between the fixed and the moving jaw becomes smaller, and the material is crushed; When themoving jaw rises, the angle between the fixed and the movable turns becomes larger, and the movable jaw leaves the fixed plate under the action of the pull rod and the spring, and the crushed material is discharged from thedischarge opening.

5. Pictures

6. Working Site