Roller CrusherStone Cone Single Double Small with High Capacity

We manufacture Roller CrusherStone Cone Single Double Small with High Capacity. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

Double Roller Crusher has simple structure,which is high efficient and energy saving.It widely used in industrial fields such as cement, chemical, electric power, metallurgy, building materials, mineral processing, refractory materials, etc.It can crush medium and hardness material,such as limestone,slag, coke, coal, etc.

2. Main Features

1. Simple structure, light weight and small body, it is convenient to operate and maintain.

2. It is equipped with dustproof plate in the inner part, which has good sealing performance, avoid splashing of fine materials after crushing,and there has less dust and low working noise.

3. The abrasive roller body is redesigned and optimized. The machine does not need to change the roller body all the life.

4.Roller crusher is equipped with replaceable wear-resistant lining plate. The wear-resistant lining plate adopts domestic advanced wear-resistant materials, which has the advantages of long service life and convenient maintenance.

5. It is equipped with safety protection devices. When accidental metal iron pieces enter the crushing chamber, the protective device acts well and the iron leakage device runs normally.

6. Low operating cost, stable operation, high efficiency and energy saving.

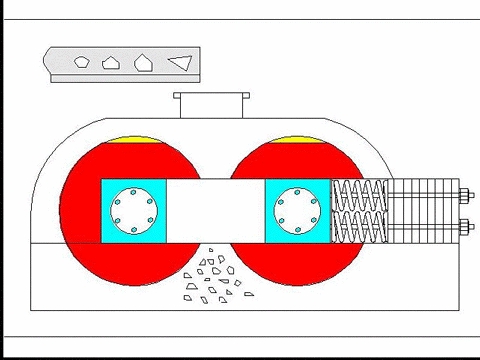

3. Working Principles

When the roller crusheris working, raw material falls into the two rolls through the feeding opening to crushing,the finished material naturally falls. In the case of hard or unbreakable stones, the rollers can be automatically retracted by the action of hydraulic cylinders or springs, so that the gap between the rollers is increased,the hard or unbreakable stones are dropped to protecting the machine from damage. The two rollers that rotate in opposite directions have a certain gap, the gap can be changed to control the discharge size of the product.

4.Technical Data

Model | Feeding size(mm) | Output size(mm) | Capacity (t/h) | Motor (kw) | Weight (kg) |

2PG-400*250 | ≤25 | 1-8 | 5-10 | 11 | 1500 |

2PG-500*400 | ≤30 | 1-10 | 8-20 | 22 | 3200 |

2PG-610*400 | ≤40 | 1-20 | 13-35 | 30 | 4500 |

2PG-610*800 | ≤40 | 1-20 | 15-40 | 37 | 12250 |

2PG-750*500 | ≤45 | 1-20 | 15-40 | 37 | 12250 |

2PG-750*700 | ≤45 | 1-20 | 20-50 | 44 | 14000 |

2PG-900*500 | ≤55 | 1-40 | 20-50 | 44 | 14000 |

2PG-900*900 | ≤55 | 1-50 | 20-70 | 37*2 | 16800 |

2PG-900*1200 | ≤55 | 1-50 | 25-90 | 55*2 | 20800 |

2PG-1200*1000 | ≤70 | 1-60 | 25-100 | 45*2 | 40200 |

2PG-1200*1200 | ≤70 | 1-60 | 30-120 | 75*2 | 41980 |

5. Pictures

6.Working Site