VSI Crusher Stone Vertical Shaft Impact Crusher for Sand Making

We manufacture VSI CrusherStone Vertical Shaft Impact Crusher for Sand Making. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

The VSI crusher is the most advanced sand making machine, which can save energy more than 50% compare to the traditional sand making machine. This machineis specially designed for highways, high-speed railways, high-rise buildings, municipal, hydropower dam construction,concrete mixing stations and other fields.It is necessary equipment for artificial sand making and stone shaping.

2.Features

1.Compareto the traditional sand making machine,VSI crusher owns higher capacity,its performance is stable.

2.Distribute wimble has two functions,and it realizes the two feeding ways exchange.

3.It has many crushing cavities,and the finalgrains are even and excellent.

4.There has special seal device in the below of the shaft,which guarantee it will not leak oil even there has no seal.

5.The around plates can be change after they are break,which improve the efficiency of raw materials.

6.The deep cavity rotor has an optimized design and the material throughput rate has increased about 30%.

7.Environmental protection, energy saving, less dust, low noise

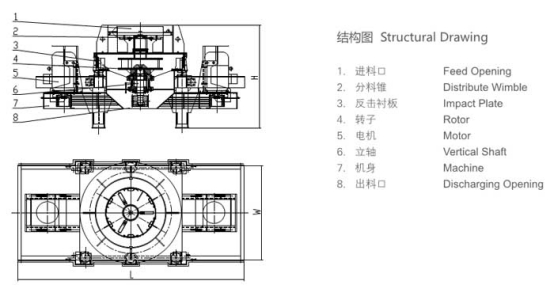

3. Structure

4. Working Principle

The VSI crusher uses advanced selective crushing principles,and it directly applies sufficient kinetic energy to the material and converts the kinetic energy into impacts to the crushing energy required by the material. The material is basically broken along its natural texture surface and cleavage surface, the grain shape is good and its consumption is low.

It realizes the conversion of the two working principles of "stone to stone" and "stone hitting iron". The material falls vertically from the upper part of the machine into the impeller which has a high-speed rotation. Under the action of high-speed centrifugal force, it produces high impacting and smashing with other materials which is around the impellers.After the materials collide with each other,the smashing material is discharged directly from the lower discharge hopper and forms a closed circuit for multiple cycles, then through the screening device to achieve the required finished grain size.

5. Technical Data

Model | Feed at center&sides | Feed at center | Soft Material | Hard Material | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

Capacity (t/h) | Max.Feeding (mm) |

VSI7611 | 120-180 | 60-90 | 35 | 30 | 1700-1890 | 4-55×2 | Y250M-4/55 | 4100×2250×2258 |

VSI8518 | 200-260 | 100-130 | 40 | 35 | 1520-1690 | 4-90×2 | Y280M-4/90 | 4140×2280×2425 |

VSI9526 | 300-380 | 150-190 | 45 | 40 | 1360-1510 | 4-132×2 | Y315M-4/132 | 4560×2450×2780 |

VSI1140 | 450-520 | 225-260 | 50 | 45 | 1180-1310 | 4-200×2 | Y315L2-4/200 | 5100×2690×3200 |

6. Pictures

7. Working Site